International(Quality)Standards

ISO9001 registered

(Oil and fuel filters)

Oil Filter Type

Full Flow Type

Oil Filtering Method

Product Example

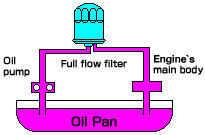

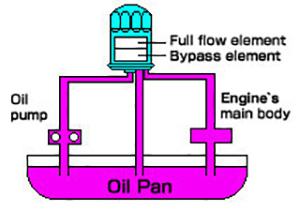

| ▶ Oil Flow Method |

| All the oil sent from the oil pump is filtered and then fed by pressure to the engine`s main body. |

| ▶ Features |

| Requires a small installation space since the filter is used alone in most cases. Currently, most widely used for gasoline-powered vehicles. Uses an appropriate filter element that enables maintenance of the oil pressure required for the engine and effective filtering of particles that may wear the engine. |

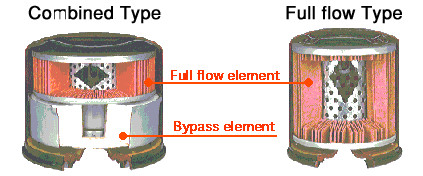

Combined Type (full-flow/bypass combined type)

Oil Filtering Method

Product Example

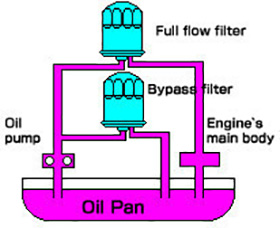

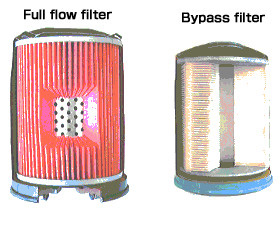

| ▶ Oil Flow Method |

| The oil fed by pressure from the oil pump is split into a full flow filter and a bypass filter (the filters are provided in their own separate cases). The oil passing through the full flow filter is fed by pressure to the engine`s main body, while the oil passing through the bypass filter is returned to the oil pan. |

| ▶ Features |

| This filter type is widely used for diesel-powered vehicles. The bypass filter is used to eliminate carbon dirt and particles that cannot be caught by the full flow filter. For this, pores on the filter element are made smaller. As a result, resistance of oil pressure in the bypass filter is higher compared to that in the full flow filter, taking more filtering time. |

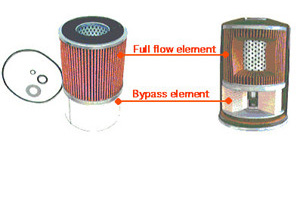

Combined Type (Integrated Type)

Oil Filtering Method

Product Example

| ▶ Oil Flow Method |

| Unlike the full-flow/bypass combined type, the oil from the oil pump is not split. All the oil from the oil pump is sent to a filter unit, where it passes through the full flow and bypass elements provided inside the unit. After being filtered, the oil flows in the same way as the full-flow/bypass combined type. |

| ▶ Features |

| Increasingly used for diesel-powered vehicles since this type requires a smaller space than the full-flow/bypass combined type. However, the internal structure is more complicated. Employs a special structure that provides internal oil pressure difference to allow both the full flow and bypass elements to maintain their specified filtering ratio. |

Air Filter

Air Filter Clogging

Clogging of the air filter decreases fuel consumption efficiency.

Replace the air filter periodically to gain the best engine performance.

After driving 5,000 km

After driving 10,000 km

After driving 20,000 km

Air Filter Type

Viscous Type

| ▶ Features |

| Dust adhering to the filter element surface absorbs oil, forming filter layers consisting of porous dust layers. Eliminates the need for cleaning. Suitable for paved roads since this type absorbs oil carbon dust well. |

Product examples

Dry Type

| ▶ Features |

| Absorbs dust inside as well as on the filter element surface. Suitable for non-paved earthy or muddy roads since this type absorbs sandy dust well. |

Product examples

Cyclone Type

| ▶ Features |

| Collects dust into a dust pan by circulating the intake air using blades to separate it by centrifugation. Provides a longer service life than the other types. Widely used for large vehicles and construction vehicles. |

Product examples

Fuel Filter

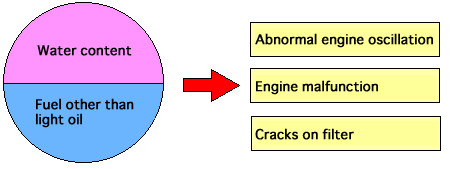

Failing to drain water will result in engine problems due to collection of water in the filter!

Diesel-powered vehicles require periodic replacement of filter or water drainage since water has an adverse affect on the engine. If you fail to do so, the following symptoms may occur due to a variety of inter-connected reasons.

Fuel Filter Type

For gasoline-powered vehicles

Product examples

For diesel-powered vehicles

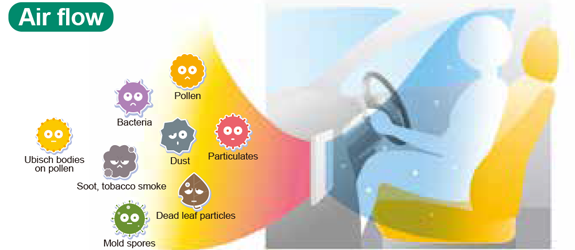

Cabin Filter

A cabin filter is installed in your car as well.

What is a cabin filter?

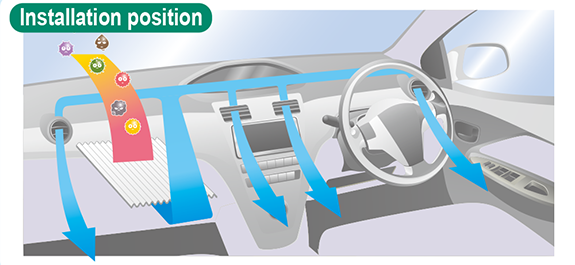

Vehicle air conditioning unit cabin filters are built into the front units of air conditioning units. They are designed to remove dust, pollen, and particulates, etc contained in external air supplied to the interior of vehicles, and clean the air inside vehicles through circulation. In addition, these are superior products that allow vehicles to sustain stable air conditioner airflows while maintaining superior dust removing performance, and keeping vehicle interior environments comfortable.

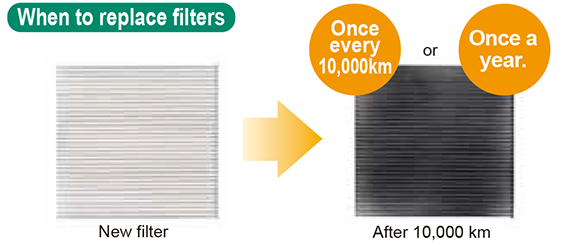

When to replace filters

Filters should be replaced once every 10,000 km, or once a year.

*Replacement periods will change according to driving conditions and usage. In particular, early replacement is recommended when filters are used in areas with heavy traffic volumes and high levels of particulates. Carry out replacements in accordance with the maintenance manual provided with your vehicle.

Replacement and installation

Cabin filters are generally installed in the backs of glove boxes. Please refer to the installation manual provided for details regarding installation positions.

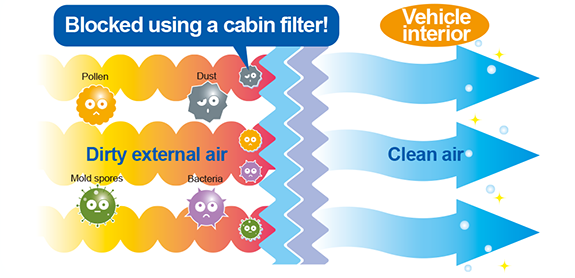

A cabin filter that significantly cuts air pollutants.

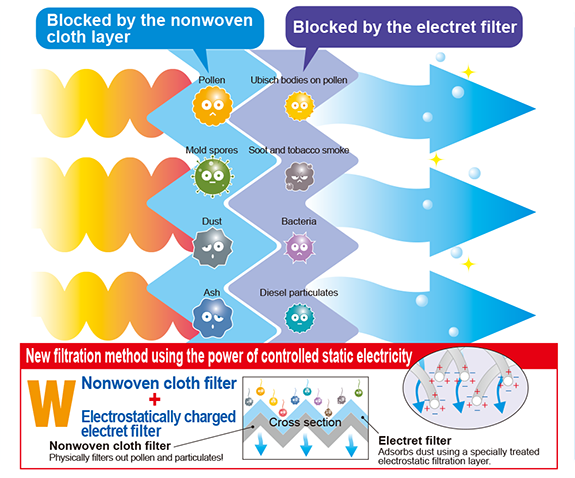

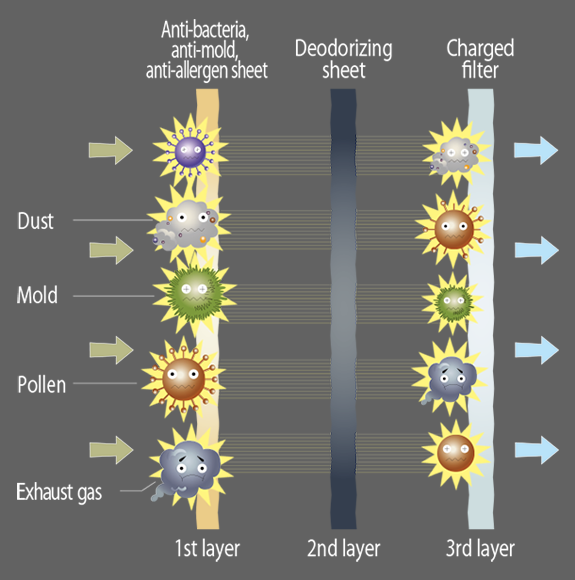

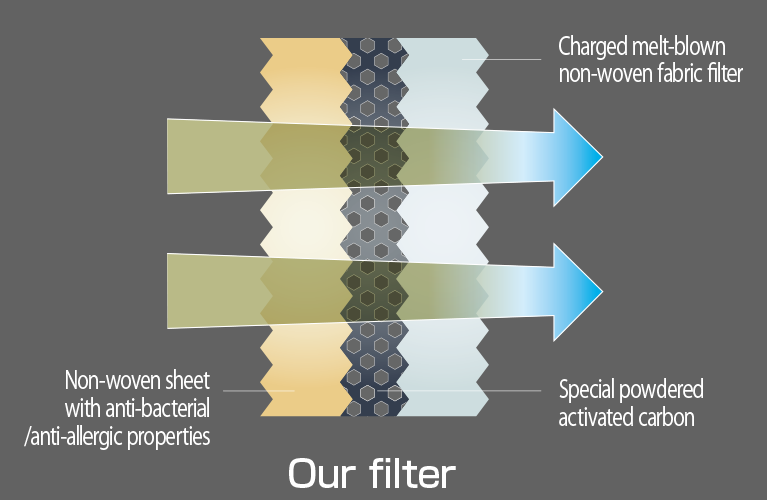

Through the use of a new filtration method consisting of a double filter structure employing synthetic fiber nonwoven cloth and an electrostatically charged filtration layer, we have produced a filter that is capable of not only capturing dust, but also adsorbing, trapping,and completely removing fine particles including allergens such as pollen and particulates,etc, which were not able to be removed from air up until this point in time.

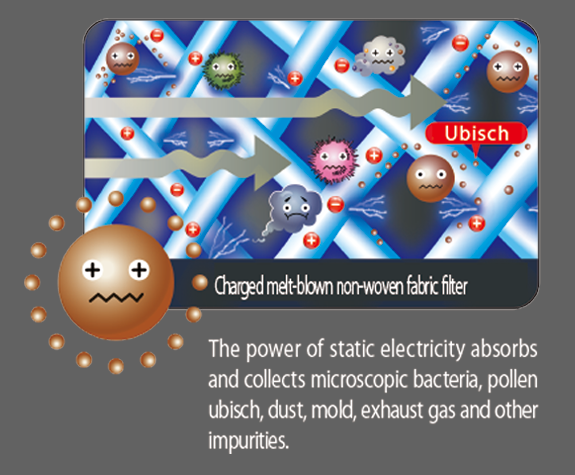

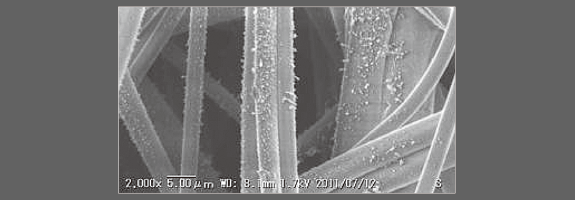

Revolutionary double filter structure

We have created a revolutionary double filter structure by interweaving a special high performance electret filter into a synthetic fiber nonwoven cloth filter using our own unique technology. As a result, we have succeeded in physically trapping relatively large particulate matter using the nonwoven cloth filter, and adsorbing and trapping fine particulate matter of less than 1 micron in diameter including allergens such as pollen, dust, and particulates, etc (which were not able to be removed from air up until this point in time) at high levels of efficiency using the electrostatic filtration layer of the electrostatically charged electret filter. In addition, the use of this adsorption and trapping method employing static electricity maintains extended, stable filtration performance without increasing the airflow resistance of air conditioners, and has realized effective trapping capabilities.

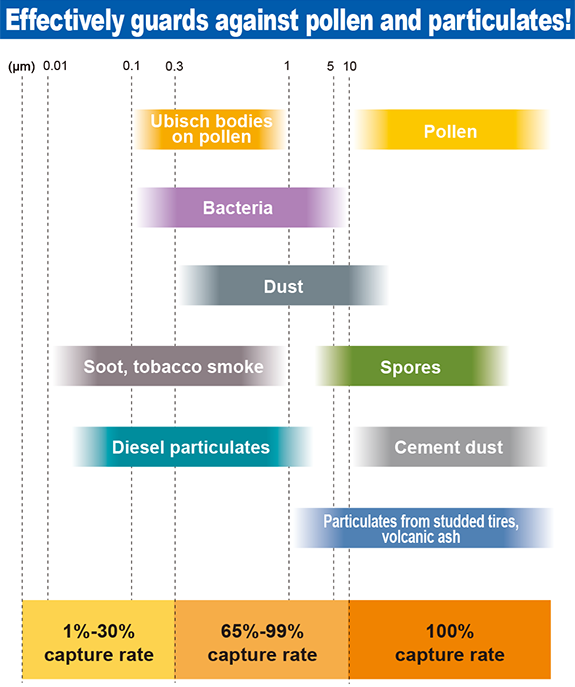

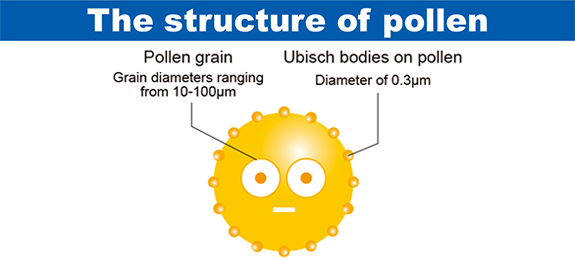

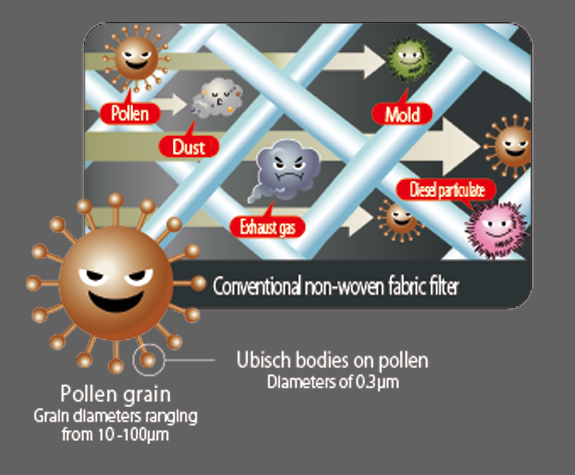

Completely removes particles larger than 3 microns in diameter

Completely removes particles larger than 3 microns in diameter (pollen, dust, particulates, etc).

Also removes fine particulate matter of less than 1 micron in diameter (Ubisch bodies on pollen that cause hay fever, bacteria, soot, etc) with high rates of efficiency.

Filter filtration range

In addition to pollen from plant species including cedars and cypresses,etc, this filter is also capable of blocking fine pollutant particles including diesel particulates, which were difficult to remove up until this point in time. Needless to say, the air that is circulated inside vehicles also passes through the filter, so that air that enters vehicles when people get in and out of them is also cleaned.

One of the causes of hay fever is thought to be Ubisch bodies on pollen.Ubisch bodies are fine particles that break away from the surfaces of pollen grains, and are believed to be one of the causes of allergic diseases, etc.

| Adsorption Power |

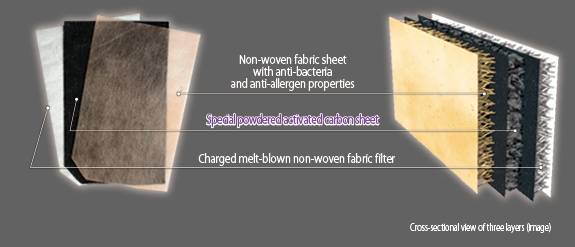

| Featuring a charged melt-blown non-woven fabric filter The third layer is a melt-blow non-woven fabric filter with individual fibers that have been semi-permanently charged (electrostatic charge). Static electricity has the effect of thoroughly absorbing and collecting allergens such as microscopic pollen and dust, as well as diesel particulate and exhaust gas which cause atmospheric pollution. |

Adsorption and collection of 0.3 micron particulate (image)

Adsorption and physical collection of 7-8 micron particulate

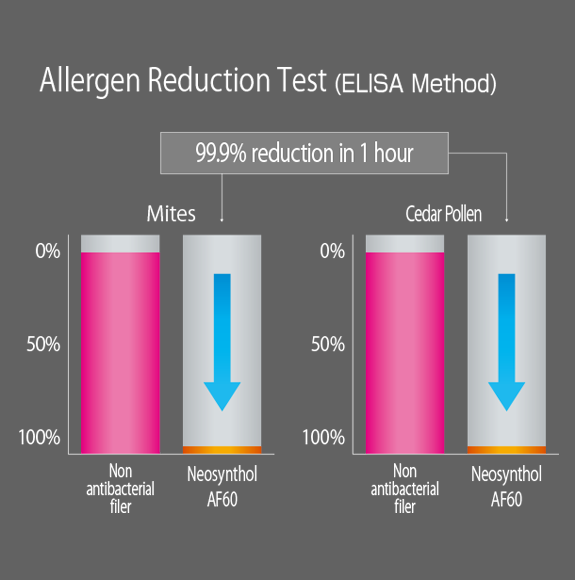

| Suppression Power |

| Includes the anti-allergic agent Allersave (a natural polyphonic) and anti-bacterial agent Neosynthol The first layer is a compound sheet featuring Allersave, which is an anti-allergic agent using natural plant extracts as active ingredients, and Neosynthol, an anti-bacterial agent which suppresses the proliferation of mold and bacteria coliform. In addition to reducing pollen, mites and other allergens caught by the filter, this design suppresses bacteria which reproduces in dust and mold, thus maintains clean air from the air conditioner. |

99% reduction in virus!

EX

type uses special filter media certified by SEK Antiviral Finished Product to

reduce certain viruses and keep the air inside the car clean.

What is SEK Antiviral Finished Product?

It is certified by the Japan Textile Evaluation Technology Council (JTETC). Indicates that the product has been approved by an official organization as an antiviral finished product.

What standard is it?

It

is defined by international standard ISO18184. Only those that meet strict

inspection standards are allowed SEK Antiviral Finished Product.

(Test

virus: ATCC VR-1679)

What products are certified?

It

is certified for various textile products, including medical supplies such as

lab coats and masks.

Note

l This antiviral finished products

are not intended for the treatment or prevention of sicknesses.

l Antiviral test is conducted

with virus strains ATCC VR-1679 (with envelope) that have been left for two

hours at 25 ° C.

(Test virus is only

described.)

This antiviral

finished products do not inhibit the function of virus.

| Deodorization Power |

| Featuring a special powdered activated carbon sheet The second layer includes special powdered activated carbon with outstanding deodorization performance. Moreover, the inclusion of an adsorbent agent further increases this deodorization performance. The filter absorbs impurities such as hydrogen carbonate gas, alkaline gas and acidic gas, maintaining stable and long-term deodorization capability. |

| Airflow Power |

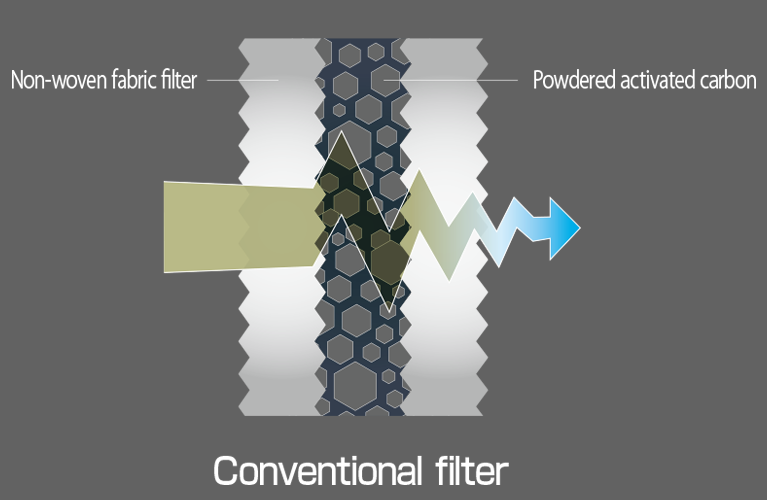

| Charged melt-blown non-woven fabric filter + Special powdered activated carbon sheet High breathability is yet another feature of the third layer, a charged melt-blown non-woven fabric filter which uses static electricity to absorb impurities. Furthermore, the special powdered activated carbon used in the second layer has been formed into a thin sheet to prevent the activated carbon from interfering with breathability. This maintains quiet and stable airflow over the long-term while also ensuring breathability. |

Replacement of the Cabin Filter

The Cabin Filter can be replaced easily in most car models.

※ The replacement procedure and the part number of the cabin filter is different for each car models.

Please check carefully the parts number and car models in the catalog when it is replaced,

And please see firmly to the owner's manual concerning how to replace it.